Laoli Technology

The main business scope is: design, manufacture, installation, commissioning, engineering design, technical consultation and training, new product development and development of production equipment such as food, dairy products, soybean deep processing, biopharmaceuticals, etc.

Continuously digest, absorb and utilize international advanced technology, and strive to improve the company's own R & D capabilities and manufacturing levels, and sincerely provide customers with excellent equipment and excellent services, and do more to promote the technological progress of China's food and dairy industries. contribution.

Heilongjiang LaoLi Technology Co., Ltd. is a wholly-owned enterprise in the United States. It was registered in Harbin, China in 2003. The production base Anda Labor (Food) Machinery Co., Ltd. was completed and put into operation in 2006 with a registered capital of 20 million yuan. The company's main business scope is: food, dairy products, soybean deep processing, biopharmaceutical and other production equipment design, manufacturing, installation, commissioning, engineering design, technical consultation and training, new product development and development, etc. The company's production base has invested 120 million yuan, covering an area of 40000 square meters and a construction area of 15000 square meters. All kinds of processing equipment are advanced and complete. The core members of the company are composed of American food machinery experts, domestic dairy machinery experts, spray drying equipment experts, dairy technology experts and the former backbone of production technology in Heilongjiang dairy machinery industry. The staff is 230, and the key positions have been trained by foreign companies.

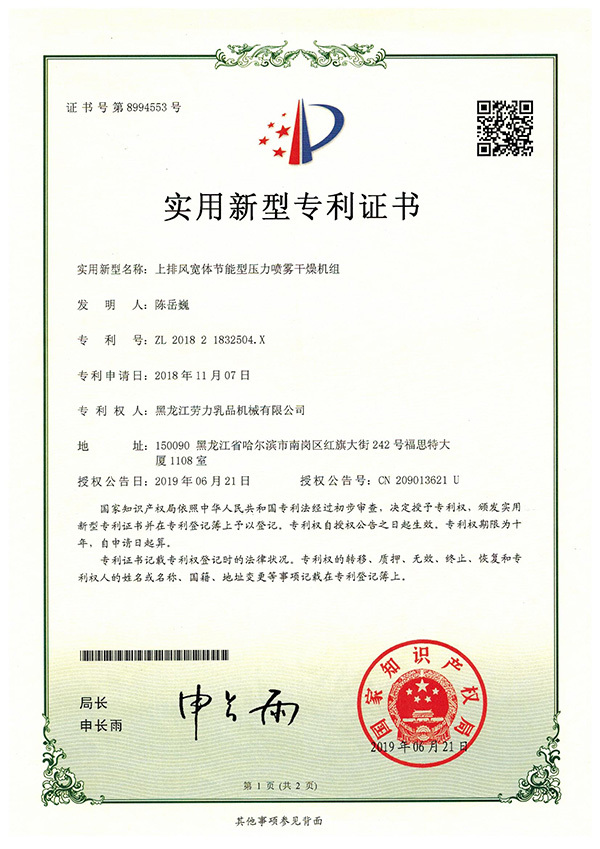

The company relies on the technical support of "American labor" in the design and research and development of equipment, and actively promotes the progress of equipment in the domestic dairy industry and soybean deep processing industry. Among them, the third-generation international new type "upper exhaust vertical pressure spray drying separation device" developed and produced by digesting and absorbing international advanced technology has won the national utility model patent. This technology has been well promoted in the dairy and soybean products industries at home and abroad. Application, because of its low energy consumption, good product freshness, no manual cleaning, no pollution, easy control and other characteristics, is well received and praised by customers; the "special dry powder mixer for infant formula milk powder" developed and produced by digesting and absorbing international advanced technology has also won the national utility model patent. The machine is evenly mixed, reduces the degree of particle damage, reduces the generation of net electricity, and fills the formula milk powder The blank of no special dry mixer has made a new breakthrough in the dry production of formula milk powder technology. The machine won the second prize of China Dairy Science and Technology Progress Award in 2017 by China Dairy Industry Association ". Many turnkey model projects produced by the company, such as the new upper exhaust pressure spray drying unit, the new multi-process falling film evaporator, the large outdoor storage warehouse, the multi-functional self-priming mixing system for producing formula milk powder, the combined pretreatment system, the full-automatic CIP system, the overall process pipeline installation, the dry process infant formula milk powder production line, the special medical food production line and so on, have been well received by experts and customers at home and abroad, in the formula milk powder, soybean milk powder, soybean (rice) protein, soybean (rice) peptide, food additives, bioengineering, traditional Chinese medicine processing, special medical food and other fields of technical performance are in the leading level in China.

Our company's purpose is to continuously digest, absorb and utilize international advanced technology, and strive to improve the company's own R & D capabilities and manufacturing levels, and sincerely provide customers with excellent equipment and excellent services, in order to promote China's food and dairy industry. Make more contributions to technological progress.

Honor

Quality Management System Certification

Certificate

Technical Excellence Award

Certificate

Patented technology

Utility Model Patent Certificate

Utility Model Patent Certificate

Utility Model Patent Certificate

Utility Model Patent Certificate

Utility Model Patent Certificate